Vulcanized Ceramic Rubber Steel Composite Sheet as Chute Lining

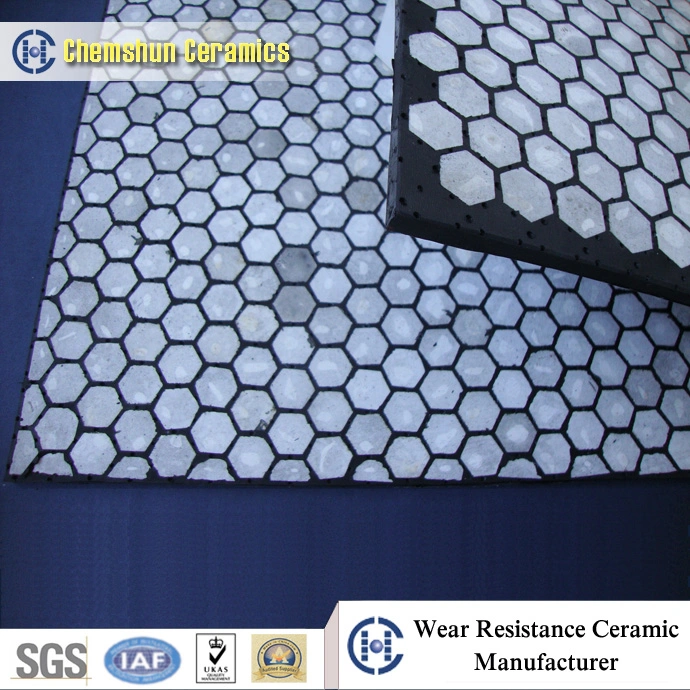

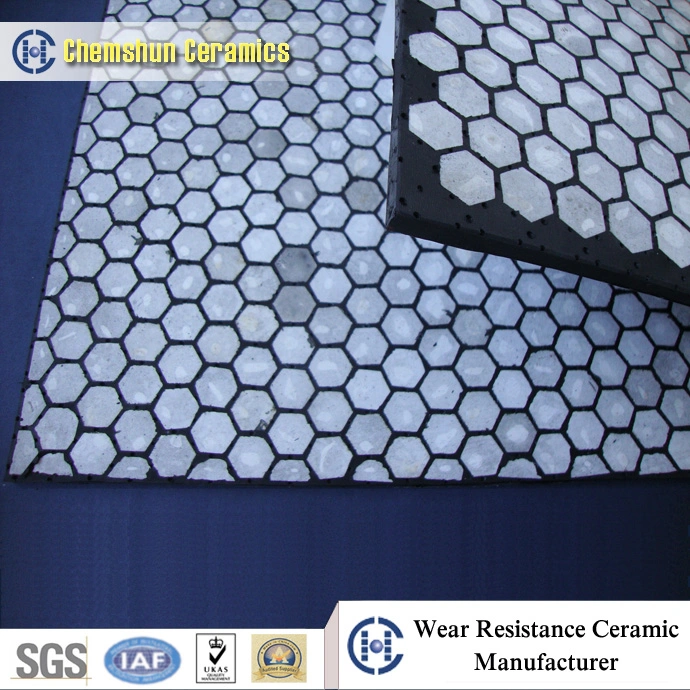

Abrasion resistant Rubber wear ceramic liner is new generation composite panels, a combination of wear resistant alumina ceramic cylinders/ceramic tiles vulcanized in resilient rubber base. The alumina ceramic surface provides exceptional resistance to wear, while the elastic property of the rubber effectively dampens the impact forces which can crack the ceramics. Rubber also helps to substantially reduce the vibrations, sounds, and the impact shock generated from impacting rocks.the panel is suitable for feeders, chutes, bins, transfer points, in conveyor systems, screen feed plates, mill discharge chutes, bunker etc.

2: Chemshun Ceramics can be vulcanized in rubber sheet :

1) Alumina ceramic plain tile

2) Ceramic hex tile

3) Square ceramic mosaic tile

4) Wear ceramic cylinder

Ceramic rubber wear liner with angle can be custom produced by Chemshun Ceramic Company

3: Ceramic Wear Plate application

4: Property and sizes

5: Technical Data

Abrasion resistant Rubber wear ceramic liner is new generation composite panels, a combination of wear resistant alumina ceramic cylinders/ceramic tiles vulcanized in resilient rubber base. The alumina ceramic surface provides exceptional resistance to wear, while the elastic property of the rubber effectively dampens the impact forces which can crack the ceramics. Rubber also helps to substantially reduce the vibrations, sounds, and the impact shock generated from impacting rocks.the panel is suitable for feeders, chutes, bins, transfer points, in conveyor systems, screen feed plates, mill discharge chutes, bunker etc.

2: Chemshun Ceramics can be vulcanized in rubber sheet :

1) Alumina ceramic plain tile

2) Ceramic hex tile

3) Square ceramic mosaic tile

4) Wear ceramic cylinder

Ceramic rubber wear liner with angle can be custom produced by Chemshun Ceramic Company

3: Ceramic Wear Plate application

| Industry | Applied Equipment |

| Mining | Discharge Chute , Transfer Chute , Reflectors And Impact Plate, Conveyor Skirt Liners, Stacker And Reclaimers, Hoppers And Silos , Bunker & Bin , Belt Stock House, Coal Feeder, Coal hopper, |

| Coal fired power plant | |

| Port Industry | |

| Steel industry | |

| Cement plant |

4: Property and sizes

| Property | Value | |

| Alumina Content | Al2O3 92% | Al2O3 95% |

| Ceramics Vulcanized | Square Mosaic Tile, Rectangle Tile , Plain Tile , Hexagonal Tile , Alumina Cylinder | |

| Ceramic Thickness | 15mm ~ 50mm | |

| Rubber Thickness | 3mm~10mm | |

| Steel Thickness | 3mm~10 mm | |

| Normal Size | 150*300 , 200*200, 300*300, 500*500, 450*300, 530*450, | |

| Sheet Structure | Ceramic Steel , Ceramic Rubber, Ceramic Rubber Steel | |

5: Technical Data

| Item | Description | Unit | Result |

| Alumina Ceramics | |||

| 1 | Alumina (Al2O3) | % | 92 / 95 |

| 2 | Density | g/cm3 | 3.64 |

| 3 | Water Absorption | % | ≤0.01 |

| 4 | Hardness | Mohs | 9 |

| Rubber | |||

| 1 | Material | NR, BR | |

| 2 | Gravity | g/cm3 | 1.15 |

| 3 | Tensile Strength | MPa | 16 min |

| 4 | Elongation | % | 400 min |

| 5 | Abrasion Loss | mm3 | ≤80 |

| 6 | Aging coefficient (70ºCx48h) | ||

| Peeling Strength | |||

| 1 | Peeling strength between rubber & ceramic | kN/m | ≥12 |

| 2 | Peeling strength between rubber & steel | kN/m | ≥12 |